Whenever you take on a major project you know, that no matter how much planning has been done or time you have, something is going to require you to spend late hours at the last minute, finishing up things that just couldn’t get done otherwise. As they say “If it wasn’t for the last minute, nothing would ever get done!” So far, from the outside you could have no idea we were building a race car. Maybe we were restoring that bug, maybe we are just making a mess. But in the last few weeks we have actually made steps that will make it apparent that we are actually building our Class 11 Desert racing machine!

We had a checklist made up and on that list were items including:

- Fabricate a transmission mount

- Locate and weld in mounting tabs

- Box in frame horns,

- install brakes, hubs and springs

- install body on pan

- Take it on up to Build by Bones to work on the cage

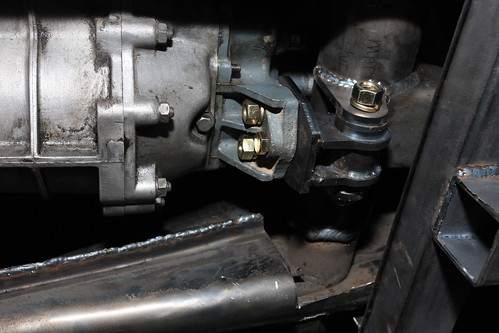

Step one, fabricate the Transmission mount. It seemed like the world was against us on this. We drew up a transmission mount and sent it to a friend to machine. Promptly his mill broke. So we converted it to a flat pack design and sent it off, to be cut on the laser and ordered some pipe for it… the pipe came in at the wrong size. We finally got the correct tubing and machined it down and someone (read Josh) forgot to get small tubing for the center of our bushing. Finally with all the parts made and located we fabricated caps that served as our bushing mold and.. the material just wasn’t working out… SO after starting again, this time with Teflon, everything worked out. Wow, what a hassle! Now it is all welded in and going nowhere.

We moved on to boxing in the framehorn. In one night, we were able to make amazing progress on this. The dynamic duo of Matt W and Josh teamed up and as Josh was cutting and fitting Matt was welding.

Once it was all in place we were able to do all the finish welding to make this thing a solid part of the car. It is an incredibly strong section now, probably stronger than it was when it rolled off the assembly line. All this actually increased the strength of the King Kong mount as well.

With the clock ticking down we put in another late night and we got the body rested nicely on the pan. Finally, we bolted up the connections and got our first glimpse of the new ride height of the car. Unfortunately we did not preload the rear suspension, so we only get to see the ride height in the front. But wow it looks good and wow, does that give us some motivation to really push on with this build!

When the body bolted on the pan, we were mostly delirious. Josh was toasting pop tarts with a blow torch, Matt (who typically makes calculous jokes) was trying to determine how many bolts we actually put in the pan and exactly, how to make the body move to the left in order to line up other holes as well.

No matter how tired you are, there are certain milestones that simply stick with you and when we saw the car sitting there, on its tires, with the suspension all jacked up and the majority of the rust work done… well we couldn’t help but stare a bit. It is quite the site to take in and it is the first time, that 2 of us can no longer simply pick up our project and move it around!

In the morning, Yves Braun stopped by with a trailer and towed or car up to Built by Bones. Grant Barclay is providing us with tools, information and fabrication expertise. We really are glad to have him on board. It is amazing to think about the spacial relations and the quick math that he and Tyler (who we dubbed “the cage whisperer’), are able to do in order to make these bends perfect the first time.

With the aid of our bumbling team we were able to get the main hoop, the x, the two side hoops and the two rocker tubes in and tacked. They all look perfect and we are glad to have a very solid cage to start out with. Currently the car is stil up at Built by Bones and over the next two weekends, we will be heading up there to talk more, fabricate and weld more until we have built the remainder of the cage.

Like I mentioned before, every project has its milestones and any long-term project has those moments of doubt. When one task begins to take to long it is tough to move on, but just in the nick of time the cage happened and it is a huge motivator! We look forward to next weekend in order to make some incredible progress on the rest of the cage and hopefully even get some seats and shocks mounted… if we are lucky! Thanks for following along. We will have more webisodes soon and if you want more details, don’t forget to check our website: www.projectbaja.com.